The Impact of Edge AI on Industrial Operations

Over the last few years, the adoption of artificial intelligence (AI) in a range of industries has transformed the way businesses are run.

Over the last few years, the adoption of artificial intelligence (AI) in a range of industries has transformed the way businesses are run. Edge AI is one of the most important developments in this area involving edge computing with AI features. The technology is transforming industrial processes by making data processing real-time and marking real time decision making where the data is created.

What Is Edge AI?

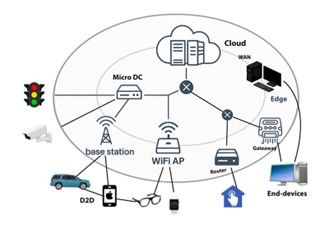

Edge AI is an implementation of the artifact of AI and machine learning models on edge devices instead of being completely cloud-based. Edge devices typically are things like sensors in the factory, CCTV cameras, cameras on robot, robots, and other pieces of industrial hardware.This allows processing and making of real-time decisions at the source, lowering latency, bandwidth requirements, and cloud-connectivity dependence.

See also: CCTV Transformation Through AI-Powered Technology: Revolutionizing Surveillance

Key Advantages of Edge AI in Industrial Operations

The analysis of data on the spot of collection in real-time by edge AI is what gives industrial systems a low latency and the ability to respond instantly to changes or anomalies in the operation. Besides swift response times, Edge AI offers enhanced data security and privacy by storing sensitive information locally, on-premise. This minimizes exposure to cyber threats and ensures compliance with data privacy regulations.

Real-world Applications of Edge AI in Industrial Operations

1. Predictive Maintenance in Automotive Manufacturing

Manufacturers used Edge AI to ensure that the health of robotic welding arms, conveyor belts, and other essential production equipment is duly monitored. These machines have multiple sensors which gather terrabytes of data (vibration, temperature, current draw, acoustic signatures).

The advantage of high accuracy predictions of possible breakdowns is that the manufacturer will be able to schedule the maintenance activities proactively during the scheduled downtime of the assembly line and will not incur the costly, unexpected cessation of assemblies.

2. Real-time Quality Control in Food and Beverage Production

High-resolution cameras capture products on conveyor belts, with Edge AI models (often using computer vision) deployed on nearby edge devices. These models are trained to instantly identify defects like mislabels, incorrect fill levels, or damaged packaging.

This real-time processing ensures defective products are immediately rejected, guaranteeing consistent quality, reducing waste, and safeguarding brand reputation by preventing recalls. The speed of Edge AI is critical, as human inspection can’t match modern production line paces.

3. Worker Safety in Oil and Gas or Manufacturing

Edge AI also increases the safety of the workers in dangerous industrial environments. On-board AI cameras can observe work-safe zones, PPE usage, and key restricted spaces by detecting hazards or non-compliance in a video feed locally. The alert is in real-time format, and it is possible to take an immediate positive action to stop accidents and minimize injuries and be within the regulations.

For further reading: PPE Detection Systems: How They Improve Safety and Save Lives

4. SOP Compliance in the Cement Industry

Edge AI solution can be applied to detect the neatness and proper arrangement of cement stacks. By using high-resolution cameras and real-time edge AI processing, the system inspects whether cement bags are stacked according to SOP guidelines, ensuring stability and safety. This automated monitoring helps prevent accidents caused by unstable or improperly arranged stacks and reduces reliance on manual inspections prone to human error.

5. People Intrusion Detection in Mineral Manufacturing

In mineral manufacturing, edge AI can be deployed to detect unauthorized personnel entering restricted or hazardous areas. AI-powered video analytics continuously monitor key zones and immediately identify intrusions. This capability enhances security by enabling rapid response to potential safety breaches or theft attempts. Integration with alarm systems and real-time notifications to security personnel ensures effective enforcement of safety protocols and regulatory compliance, reducing risks to workers and assets.

Challenges and the Future of Edge AI in Industry

Implementing Edge AI in industrial settings faces challenges like hardware investment, integration with legacy systems, and managing distributed AI models. However, ongoing advancements in hardware, standardized protocols and techniques like federated learning are making Edge AI more accessible and scalable. The future promises greater autonomy and intelligence, driving industrial innovation.

AssistX Solutions for Edge AI Transformation

- AssistX Vision: This tool uses advanced AI to power computer vision for things like real-time security, checking product quality, and making workplaces safer. It helps industries automatically watch their operations and react immediately to anything unusual.

- AssistX Sense: This product uses Internet of Things (IoT) technology for real-time monitoring and predicting issues. It helps businesses foresee when equipment might fail, plan maintenance better, and stick to safety rules.

- AssistX Lite: This solution is designed for efficient data compression and working well even with slow internet. This means even places that are far away or have bad internet can still benefit from smart monitoring and data insights.

By using AssistX products, companies can speed up their move to digital systems, make their operations more efficient, and build stronger businesses in this new age of Edge AI.

To conclude, the rapid adoption of Edge AI is fundamentally reshaping industrial operations by enabling real-time data processing, predictive maintenance, quality control, and enhanced worker safety at the source of data generation. However, to fully realize these benefits, organizations need robust, scalable, and efficient solutions that can seamlessly integrate with existing infrastructure while overcoming challenges such as bandwidth limitations, data storage, and system compatibility.

See also: People Counting Solution for Malls: Enhancing Customer Insights and Safety